Our core capabilities include:

At Marchinto, we uphold the highest standards of quality and compliance through rigorous testing and inspection. Our build-to-print expertise ensures every wire harness and cable assembly meets exact customer specifications while delivering reliability in mission-critical applications.

Testing & Inspection

First Article Inspection (FAI) & PPAP Support – Providing comprehensive verification for initial production runs and ensuring consistency in quality for large-scale manufacturing.

In-Process & Final Quality Audits with Full Traceability – Maintaining strict oversight throughout production to meet customer specifications while ensuring product integrity from start to finish.

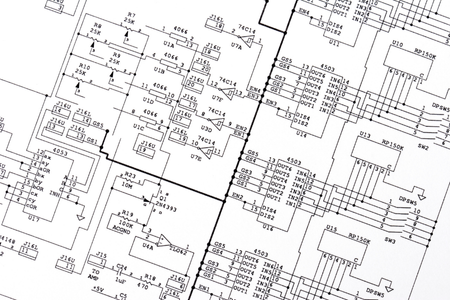

100% Continuity & Hi-Pot Testing – Verifying electrical integrity and insulation resistance for safe, high-performance operation.

Functional & Parametric Testing – Ensuring components operate within design parameters to guarantee seamless performance.

Acceptability Requirements to IPC/WHMA-A-620, J-STD-001, IPC-610A – Conducting meticulous inspections to ensure compliance with industry standards for workmanship and reliability.